Propeller Boss Cap Fins

1. The story of Propeller Boss Cap Fins (PBCF) – A game-changing solution for marine industry

It is conventionally known that the majority of ships are propelled – or actuated – by installing a propeller in the area of the rear of the hull. so that it can rotate effectively under the water to orientate the ships.

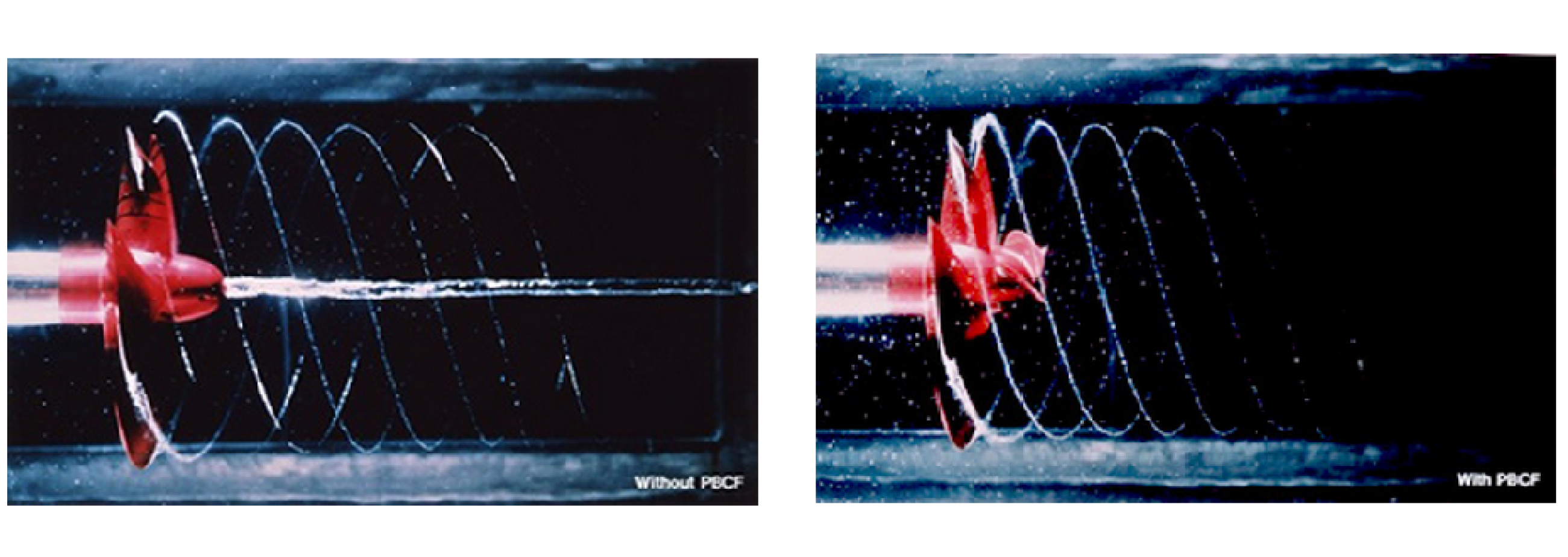

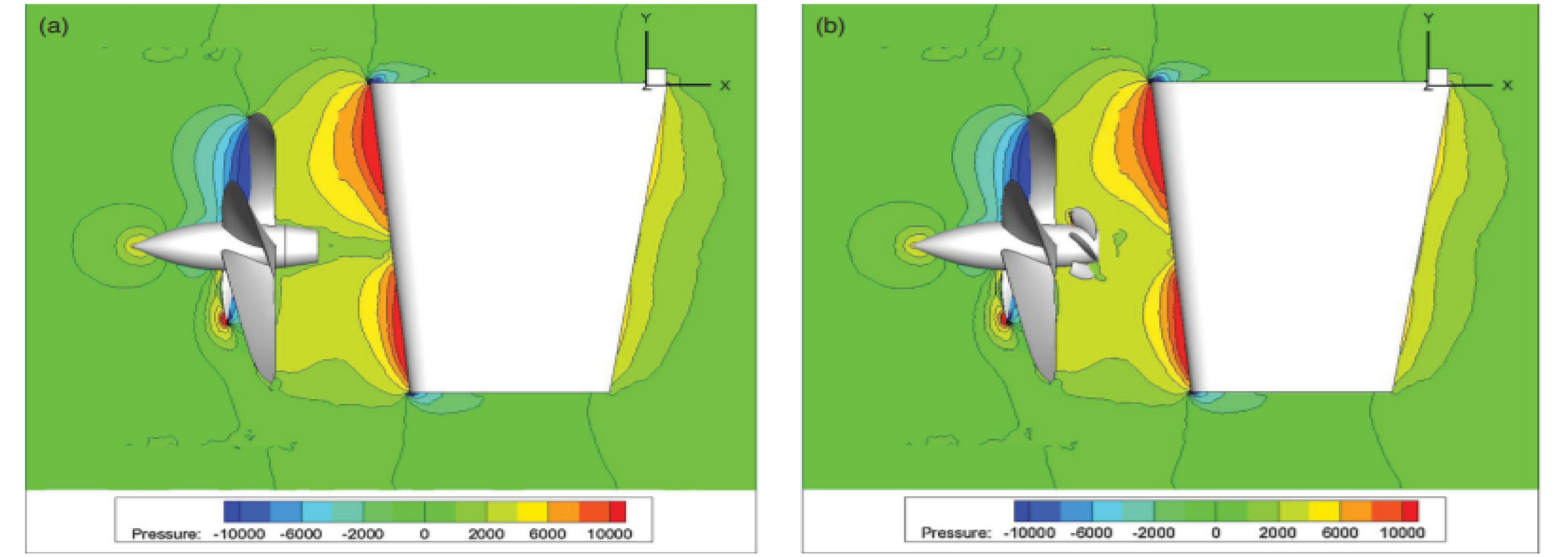

When the ship is moving forward swimmingly, the traditional propeller is regarded as an outstanding invention because it can propel this ship at a constant speed. However, in practical circumstances, this ship certainly has to rotate occasionally that results in a rotating flow behind the propeller that can somehow hinder the propulsion orientation. Technically, it refers to the conventional boss cap that usually generates a “hub vortex” behind the center of the propeller, which eventually mitigates the overall efficiency.

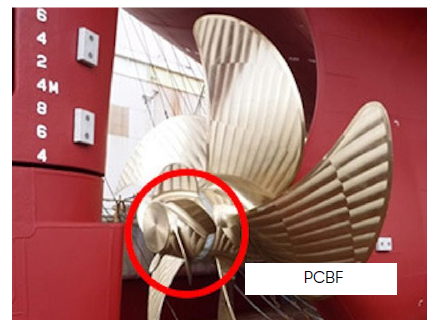

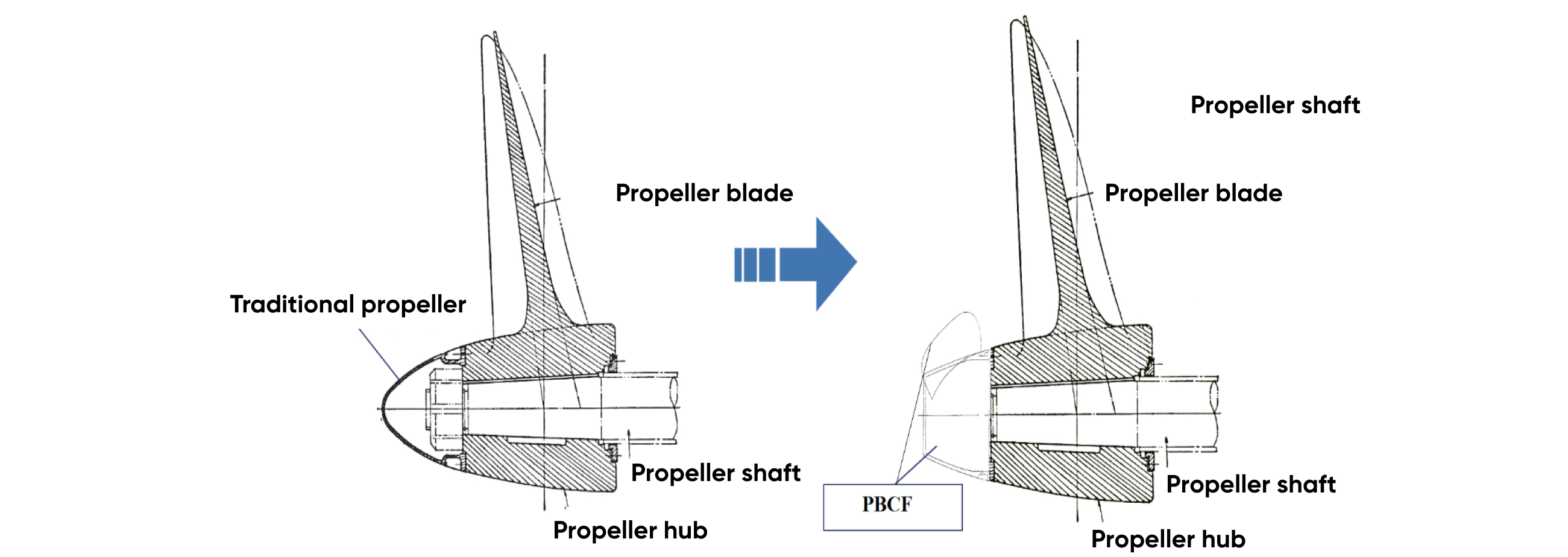

That explains why the PBCF has been invented and developed to diminish the occurrence of this hub vortex. It is identified as supportive fins to cover the boss cap with the objective of eliminating the hub vortex as downward flows after the blade are blocked by the installed fins.

That explains why the PBCF has been invented and developed to diminish the occurrence of this hub vortex. It is identified as supportive fins to cover the boss cap with the objective of eliminating the hub vortex as downward flows after the blade are blocked by the installed fins.

In essence, the main functions of the PBCF are fostering thrust and minimizing shaft torque, with the ultimate goal to enhance propeller efficiency.

2. Key advantages to consider the PBCF for your propellers

2.1 Energy saving implies reduction in various detrimental aspects

• It is experimentally projected that the PBCF can save 3 – 5% of ship’s fuel consumption, thus leading to cost reduction and optimization in operating costs.

• When the ship can function more effectively, it consrequently reduces noise and vibration at the stern of the ship.

• When the ship can function more efficiently, it reduces the rudder corrosion and various types of gas emissions. The Propeller Boss Cap Fins (PBCF) eliminate the vortex at the water exit area behind the propeller. This vortex is the cause of propeller effciency losses, noise, vibration, and rudder corrosion.

2.2 The straightforward way of installation

It is fundamentally documented that the installation of the PBCF will not mandate any remarkable modification. To put it in brief, it is just like a normal boss cap to cover the propeller. It implies that the PBCF can be installed on either new or old ships, merely by replacing the currently installed boss cap with the PBCF.

Nevertheless, in order to analyze and manufacture the most compatible PBCF for each specific ship, there are several steps that are highly recommended to implement as follow:

2.2.1 Mandatory steps to implement PBCF installation

Step 1: Calculate the relationship between power, speed, and RPM during sea trials to compare these with the recorded sea trial results,

which are considered the most reliable. This comparison is essential to validate the accuracy of the CFD model against the actual sea trial outcomes.

Step 2: Calculate the relationship between power, speed, and rotational speed after drydocking for repairs (including hull and propeller cleaning) in the operating waters, in cases where a PBCF (Propeller Boss Cap Fins) has not yet been installed (step 2 to facilitate the comparison of fuel savings achieved by installing additional PBCF on the vessel compared to before its installation).

Step 3: The geometric parameters of the PBCF need to be optimized:

– Diameter (DPBCF);

– Length of the PBCF blade (PBCF chord); Phase lag angle between the main propller and PBCF; Pitch of the PBCF (BPCF Pitch); Position along the length of the PBCF (xPBCF/D);

– Blade rake angle (rakePBCF/D);

– Blade thickness.

Step 4: Implement the 2D design drawings and construction drawings for the PBCF arrangement

Step 5: Establish a technical procedure for the deployment and installation of Propeller Boss Cap Fins (PBCF) on the vessel.

Step 6: In collaboration with our partners, assess the effciency of PBCF solution by comparing pre-installation and post-installation performance, utilizing actual onboard measurement data.

2.3 Worry-free about maintenance cost

The PBCF has a simple structure that requires minimal maintenance cost, or even nearly zero maintenance cost. Conversely, its effective functions can be prolonged as long as the lifetime of the ship.

2.4 The PBCF as a contributor to sustainable development

There is a substantial number of current research about sounds created by ships under the water can lead to severe impacts on the natural habitats of the ecosystem in oceans. It means that installing the PBCF can partially contribute to sustain and protect the marine environment, which explains why some regional areas have introduced specific priority for ships that have been installed the PBCF.

3. Summary

Similar to vehicles on land, ships will also be required to improve their efficiency in performance and to reduce emissions throughout its operations in the near future to fight against the global warming. The PBCF can be recognized as an outstanding solution due to its optimal and simple installation, along with noteworthy results in advancing the efficiency of marine transportation in general.